Line speed regulator - tension type line speed regulator Tension type linear speed regulator, commonly known as elastic frame. When there is a speed difference between the li...

Line speed regulator – tension type line speed regulator

Tension type linear speed regulator, commonly known as elastic frame. When there is a speed difference between the linear speeds of the front and rear unit machines, the warp tension of the fabric will change accordingly. The tension type linear speed regulator uses the change in the tension of the fabric to adjust the speed of each unit machine to achieve the purpose of automatically controlling the line speed difference between the front and rear unit machines.

According to the leisure mode of the adjustment mechanism, the tension type linear speed regulator can be divided into two types: lifting type and swing type.

1. Lifting linear speed regulator

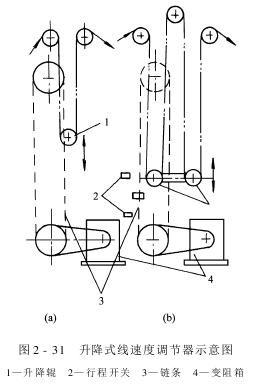

Figure 2-31 is a schematic diagram of the lifting linear speed regulator. It is mainly composed of cloth guide roller, sprocket, rheostat box and frame. According to the number of cloth guide rollers, the lifting linear speed regulator can be divided into three-roller type and five-roller type, as shown in Figure 2-31(a) and Figure 2-31(b).

In the three-roller type, one of the cloth guide rollers (commonly known as the lifting roller, also known as the tension roller) can rise and fall with the change of the warp tension of the fabric. Through the sprocket, the chain is rotated, thereby changing the change. The resistance of the resistance box makes the drive motor of the unit machine automatically adjust its speed. In the five-roller type, there are two lifting rollers, which are more responsive.

2. Swing line speed regulator

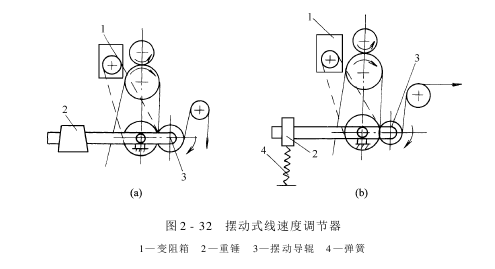

Figure 2-32 shows the swing type linear speed regulator, which can be divided into two types: heavy hammer and spring swing type. It consists of a swing linear speed buffer device and an electrical speed regulating mechanism. The basic principle is the same as that of the lifting type, except that the tension change of the fabric due to changes in linear speed causes the buffering mechanism to swing, rather than the lifting and lowering of the roller. This swing causes the chain to drive the rheostat box to change the resistance, thereby achieving the purpose of automatically adjusting the linear speed difference between the front and rear units.

AAAGFREGRTTHR

Extendedreading:https://www.yingjietex.com/product/400D-Polyester-Double-Catenulate-Dobby-OXFORD-Fabric.html

Extendedreading:

Extendedreading:

Extendedreading:

Extendedreading:

Extendedreading:

Extendedreading:

Extendedreading:

Extendedreading:

Extendedread