Water rolling machine - several commonly used water rolling equipment 1. Small diameter roll In order to improve the water rolling efficiency and obtain a lower rolling residu...

Water rolling machine – several commonly used water rolling equipment

1. Small diameter roll

In order to improve the water rolling efficiency and obtain a lower rolling residue rate, it can be obtained by reducing the diameter of the roll. Under the same pressure, a smaller diameter roll can obtain greater linear pressure and rolling point pressure. However, the stiffness of small-diameter rolls is also small, which can easily cause uneven rolling liquid. In a three-roller rolling mill, the problem can be overcome by placing a small roll in the middle. In two-roll rolling mills, this can be overcome by improving the pressurization method.

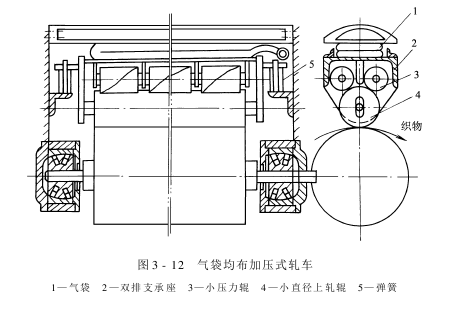

2. Air bag uniformly distributed pressurized rolling mill

Figure3-12showsaschematicdiagramofapressurizedrollingmillwithuniformlydistributedairbags.Thereisanairbagonthetopoftherollingcar.Whenthecompressedairenterstheairbag,itforcestheairbagtoexpanddownward,andpressurizesthesmall-diameterupperrollerthroughthedoublerowofsupportseatsandmultiplesmallpressurerollers.Therollingresiduerateofthiskindofrollingmillcanbereducedbyabout20%comparedwiththatofordinaryrollingmills.Moreover,therollingliquidisrelativelyuniformandthepressurefluctuationissmall.Thedisadvantageisthatthepressurizationandpressurereliefactionsarerelativelyslow,andthesurfaceoftheupperrolleriseasilywornbythepressureroller.

3.Hydraulicrollingmill

Figure 3-13 shows the schematic diagram of the hydraulic rolling mill. The upper roller is a rubber roller, fixed on the frame, and the lower roller is a small-diameter roller floating on the water, called a floating roller, made of nylon material. Using the hydraulic system, the float roller is evenly pressed up the roller. In this way, the small-diameter float roller will not deflect. However, since a hydraulic system is required and the seals are easy to wear, hydraulic rolling mills are now less commonly used.

The above-mentioned water rolling machines all rely on the rolling action of the padding car to remove moisture from the fabric. This rolling action can remove most of the moisture on the surface of the fabric. As for the moisture in the gaps between fibers or spinning yarns, it can only remove a small part. Therefore, there is a limit to reducing the rolling stock rate simply by increasing the rolling point pressure. In order to further improve the water rolling efficiency, new rollers and padding cars have emerged that use suction or blowing methods to discharge more water. These are microporous elastic rollers and compressed air injection padding cars.

4. Microporous elastic roller

Microporous elastic roller is a high-efficiency water rolling roller made of rubberized fiber sheets. Under the same conditions, its rolling residue rate can be reduced by more than 13% than that of ordinary rubber rollers.

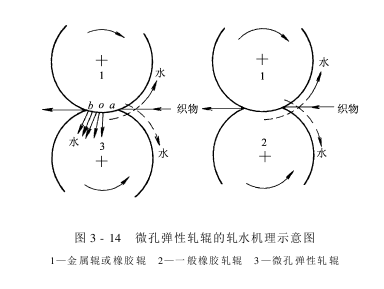

Micropores The water rolling mechanism of the elastic roller is shown in Figure 3-14. Due to the capillary action of the micropores of the roller body, when the elastic roller contacts the fabric, the moisture in the fabric is sucked into the micropores. At the same time, because the roller body has good elasticity, when the fabric enters the rolling point to the middle point of the rolling point (section a in the figure), the moisture and air in the micropores are squeezed out, and the roller removes the moisture between the spinning yarns of the fabric. Extrusion; when the fabric enters the middle point of the rolling point to the exit point (section ob in the figure), the rolling pressure decreases, the roller body rebounds, the micropores expand and recover, forming a local negative pressure, and the moisture in the fabric is sucked into the micron hole, greatly reducing the rolling residue rate.

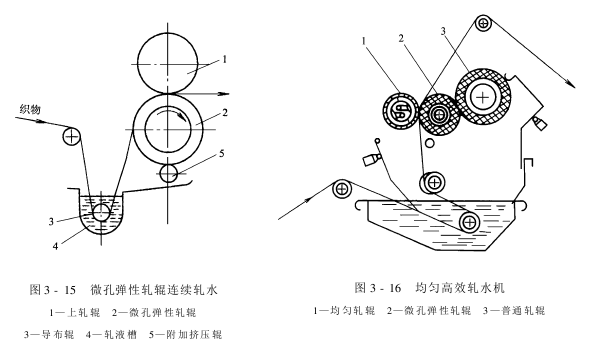

In order to make the microporous elastic roller work continuously, the water sucked into the micropores must be discharged in time. Figure 3-15 is a schematic diagram of continuous water rolling. On the other side of the rolling point of the microporous elastic roller, an additional squeeze roller is installed, which can be used to squeeze and release the moisture in the micropores of the roller in advance. The microporous elastic roller can not only improve the efficiency of water padding, but also causes little damage to the finishing fabric and the roller itself due to the low rolling pressure. It is especially suitable for fabrics such as knitted fabrics that are not suitable for withstanding high pressure. However, as the use time increases, the elasticity of the roll will gradually decrease, affecting the rolling residue rate. In addition, since it takes a certain time for the micropores of the roll to absorb water, the increase in vehicle speed is limited.

Figure 3-16 shows a uniform and efficient water rolling machine . It is a three-roller horizontal rolling mill that combines micro-hole rollers and uniform rollers. The first one is a uniform roll with a small diameter (169), the second one is a microporous elastic roll, and the third one is a general roll with a larger diameter (240). It is used as a pressure roller to reduce the deflection of the elastic roll and for additional extrusion. Roll to remove moisture from micropores.

5. Compressed air injection rolling mill

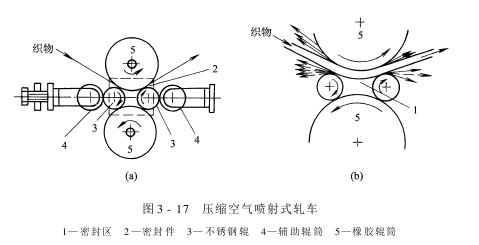

The compressed air injection rolling mill shown in Figure 3-17 is a new type of water rolling mill that combines rolling and blowing. It has high water rolling efficiency and liquid rolling. Uniform characteristics. It consists of two upper and lower counter-rotating active rubber rollers and two passive small-diameter stainless steel rollers to form a sealing area through which compressed air flows. When rolling water, the moisture on the fabric is sprayed out in the form of water droplets along with the compressed air, which greatly improves the water rolling efficiency.

This kind of padding car has low rolling residue rate, uniform padding liquid and good permeability, which can avoid fabric rolling damage and improve the feel and fullness of fabric.

Therefore, it has a certain effect on improving product quality. However, due to the high air tightness requirements of rolling cars and the high precision of manufacturing and installation, the application of this type of rolling cars has been subject to certain limitations.�.

AAAFGNHIYIYO

Extendedreading:https://www.tpu-ptfe.com/post/9321.html

Extendedreading:

Extendedreading:

Extendedreading:

Extendedreading:

Extendedreading:

Extendedreading:

Extendedreading:

Extendedreading:

Extendedread